Shinland Manufacturing Facility in Dongguan was designed in mid 2017. Decoration started in early 2018 and completed in the end of 2019. The facility is located on a 6,000m2 land with a production floor size of 10,000m2 as well. Working area with Class 300k Clean Room, overspraying and treatment area with Class 10k Clean Room, the facility meet the latest national discharge standard, and is awarded with related environmental certificate.

Workshop

The facility consists of tooling dept, plastic molding dept, overspraying dept and plating dept. All dept work together to form a complete production process.

Tooling Process

Use Swiss made steel - tool life can be 300k+ times

Multi Step Design - Product with good precision and consistency

Oil Free tooling process – Leading technology with good product quality

Precision Processing

Germany Exeron 5-axis machine – excellent precision <0.002mm

Import cutting knives, mirror polish grading – optical transfer >99%

Automatic Injection Production Line

Class 100k Clean Room Workshop. High Yield with Good Quality

Centralized material supply system, robotic arm production, labor free workshop

Import Idemitsu plastic material, UL94V(F1) Grade. Long Life and Good Temperature Resistance.

Automatic Overspraying

Class 10k Dust Free Overspraying Workshop. Good Quality with no dust particles.

Industrial Leader with 170 meter production line, AI Overspraying Process.

Vacuum Plating

Ultrathin plating technology with thickness 50-200um. Restore optical curvature and scale design >99%

Customized plating equipment. Excellent Plating Adhesion. Reflection Rate >90%

Quality Control

Shinland has passed GB/T 19001-2016 / ISO 9001:2015 quality system certifications. Product is in compliance with RoHS and REACH standard.

Quality Testing and Reliability Testing Equipment

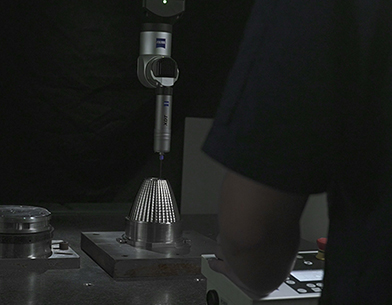

Germany Zeiss CMM Measuring Equipment

- Germany Zeiss CMM Measuring Equipment

- Provide accurate measurements to our tooling. Marble Base provides solid foundation to the machine. Zeiss Air bearings provide stable and precise measurements with less than 1um tolerance.

Quality Testing and Reliability Testing Equipment

Temperature and Humidity Control Testing Chamber

- Temperature and Humidity Control Testing Chamber

- Temperature 120C/ Relative Humidity 100%

Quality Testing and Reliability Testing Equipment

Thermal Shock Testing Chamber

- Thermal Shock Testing Chamber

- Temperature -60C to 120C. Cycling Time 10 minutes.

Quality Testing and Reliability Testing Equipment

Salt Spray Testing Chamber

- Salt Spray Testing Chamber

- Water Spray with 5% salt concentration, 80C environment

Quality System Certification

GB/T 19001-2016 / ISO 9001:2015 Quality System Certificate. National High Tech Enterprise Certificate.